Torqo Calibration Kit Standard | with Verification Beam, Frame, and Wire

Description

With a Calibration Kit [PN: T-12-162], the accuracy of your torque analyzer can be verified or a complete on-site calibration can be performed by the plant operator.

Contained in this kit is a precision Calibration Beam, a ball bearing load support assembly and the necessary hardware to use this kit.

The weights required for performing a calibration are not included in the kit but may be purchased separately.

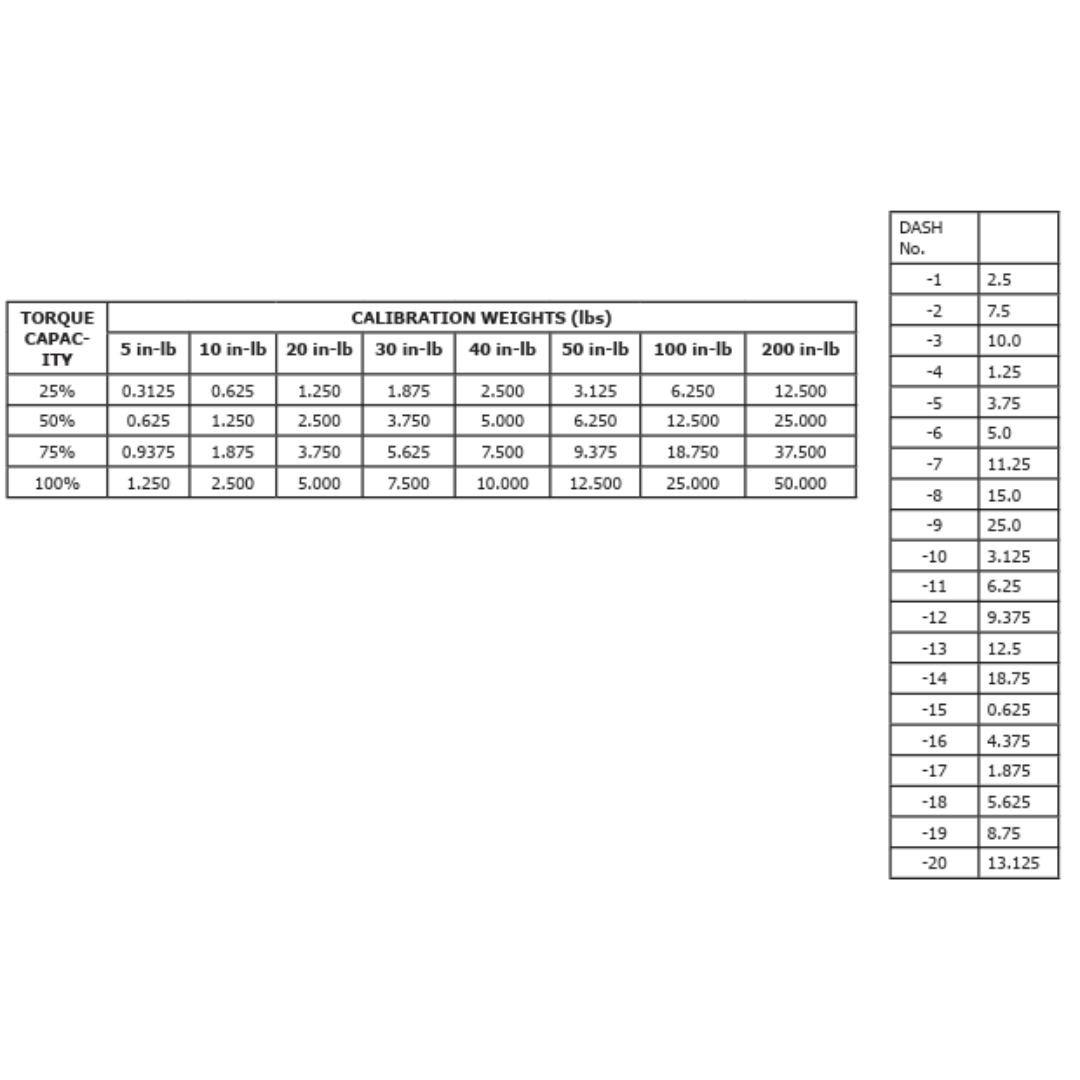

A set of weights should be selected in accordance with the information according to the charts pictured. All weights are shipped with the appropriate certification of accuracy. Please note if your requirements include a NIST certification.

The Calibration Beam is manufactured to a tolerance that will insure an accuracy of +/- 0.02%. In addition, a certificate insuring the traceability of these dimensions to NIST is supplied.

Selecting the Correct Weights

In order to perform a complete calibration, the user should have three weights. These weights in conjunction with the disk should represent 25%, 50%, and 75% of the maximum capacity of the torque analyzer that is to be calibrated. 75% and 25% combine to achieve the 100% value.

The following example shows how to calculate the values of the weights for a particular application.

- Determine value of torque analyzer to be calibrated (i.e full scale, maximum capacity)

- Compute torque in lb-in for 25%, 50%, and 75% (multiply full scale torque by percent = torque in lb/in)

- Compute weight in/lbs (divide in lb/in by radius of beam = weight in lbs).

- Radius of calibration disk = 4.0000 inches.

Example:

- Torque meter full scale 30 lb/in

- 25% x 30 lb-in = 7.5 lb/in.

- 7.5 / 4 = 1.875 lbs

- 1.875 lb. weight required for 25% calibration point

- 3.75 lb. weight required for 50% calibration point

For further questions or inquiries about our products, please Contact Us.